Why use a water-injected “wet” exhaust system?

For a products relating to this article please follow this Link

The following factors are of great importance:

- Exhaust gas temperatures can reach very high levels. A diesel engine can easily produce an exhaust gas temperature of 600° C or more.

- The speed with which sound can be transmitted through air is dependent on the temperature of the air. This applies to exhaust gases as well. The higher the exhaust temperature, the higher the speed of sound through the gas.

- The sound level, i.e. the relative volume of sound as experienced by the human ear, is in turn dependent on the speed of sound. As the speed of sound transmission reduces, so the sound level will reduce proportionally.

In the past, many boats used a “dry” exhaust system, in which the exhaust gases were transported to outside the hull without any form of cooling. The resultant hot exhaust pipe had to be thoroughly insulated, but even so, it produced a tremendous amount of noise. However, reduction of exhaust gas temperature to about 40° or 50°C can be achieved by injecting the engine cooling water into the exhaust line. This is how a “wet” exhaust system works. In addition, the typical diesel exhaust smell is also considerably reduced. A further major advantage of reducing the temperature, is the fact that all exhaust components downstream from the engine outlet can be made from rubber or synthetic materials. This permits greater design sophistication and weight reduction and ensures freedom from corrosion.

What requirements must be fulfilled by a “wet” exhaust system?

In its simplest form, a rubber hose, running from the engine directly to the transom of the boat, seems adequate enough. However, the following issues must also be taken into consideration:

- After the engine is stopped, the cooling water in the exhaust system must not be

able to flow back into the engine.

- Water outside the boat must be prevented from entering the exhaust system and

therefore the engine, through the transom connection.

In order to fulfil these requirements, VETUS offers a complete range of exhaust components made of synthetic materials, such as:

A waterlock will collect the cooling water present in the system when the engine is stopped. In addition, a waterlock has great sound-deadening capabilities and acts as a very efficient muffler. The size of the water lock is not only determined by the diameter of the exhaust hose, but also by the quantity of water that must be collected. Therefore, VETUS offers waterlocks with extra large capacity for systems with long exhaust runs.

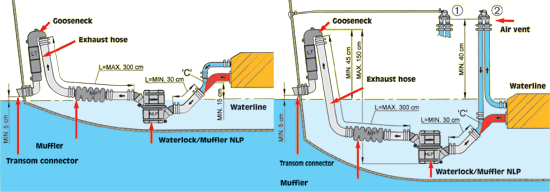

A gooseneck raises the exhaust hose above the waterline, so that water cannot backfill the exhaust system. After the engine is stopped, all cooling water in the exhaust hose will run to the lowest point of the system, which is where the waterlock should be situated. In order to limit the quantity of water, the gooseneck should be fitted as closely as possible behind the waterlock. But, if required, it may also be fitted directly onto the transom exhaust connection.

The transom exhaust connection should be fitted above the waterline, as a general rule.

We recommend VETUS rubber exhaust hose for all water-injected exhaust systems: VETUS exhaust hose is extremely flexible but it cannot collapse when subjected to heat and is resistant to exhaust gases, temperatures up to 100°C, and oil residues. These hoses are Lloyd’s approved and satisfy the SAE J2006 R2 directives.

Always fit an exhaust temperature alarm. In order to warn of excessive temperature in the exhaust system. This can happen if the cooling water flow is restricted or blocked altogether. VETUS marine diesel engines have an exhaust temperature alarm fitted as standard.

The height of the cooling water injection point into the exhaust system, relative to the external waterline, is of great importance. If the water injection point is 15 cm or more above the waterline, the cooling water may be injected directly into the exhaust system. However, if the water injection point is less than 15 cm above the waterline (or even below it) there is a risk that the cooling system will siphon water through the intake, once the engine is stopped. This water will fill up the exhaust system and eventually get back into the engine cylinders via the exhaust valves. This siphon action may be prevented by having a breather hose (1) in the cooling water line or by fitting an air vent (2).