All Vetus engine mouting absorb the propeller thrust.

The torque of an engine is one of the deciding factors for determinations of the load applied to the engine mounts. When more powerful engines are installed, it is important to use the following formula to define the load per support in kg (4 supporting points).

(engine weight in kg / number of supports) + (kW x 487 x reduction of gearbox / engine rpm x centre to centre spacing in meters of longitudinal engine bearers) = max. load per support in kg

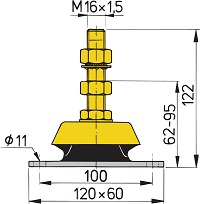

Type K50V

For smaller engines up to approx 60 kW (80hp)

Type

|

Stiffness ratio |

Min load kg |

Min. compression mm |

Max. Load kg |

Max. compression mm |

Hardness in ° Shore

|

| Vertical |

athwartships |

fore and aft |

Static

|

Static + Dynamic |

| K50 |

1 |

0.75 |

2.5 |

25 |

2 |

50 |

4 |

45 |

| K75 |

1 |

0.75 |

2.5 |

38 |

2 |

75 |

4 |

55 |

| K100 |

1 |

0.75 |

2.5; |

50 |

2 |

100 |

4 |

65 |

Technical Specification

STIFFNESS RATIO - VERTICAL

1

STIFFNESS RATIO - ATHWARTSHIPS

0.75

STIFFNESS RATIO - FORE AND AFT

2.5

MIN. LOAD (KG) - STATIC

25

MIN. COMPRESSION (MM) - STATIC

2

MAX. LOAD (KG) - STATIC + DYNAMIC

50

MAX. COMPRESSION (MM) - STATIC + DYNAMIC

4